Non-woven fabrics are widely used in medical treatment. Common masks, protective clothing, gloves, etc., the raw materials of which are non-woven fabrics. In addition to cotton packaging, non-woven packaging materials are commonly used in domestic disinfection supply centers. Cloth packaging, non-woven fabrics are a big step forward in reducing cotton dust pollution compared to cotton packaging.

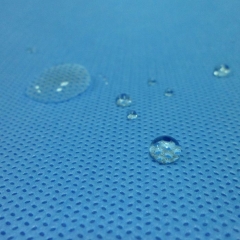

The medical non-woven fabric is used to wrap the instrument box to prevent the sterilized instruments from being contaminated again. It is breathable, waterproof, flexible, non-toxic, non-irritating, etc., and can be used for sterilized packaging such as low-temperature plasma, pressure steam, and ethylene oxide.

So what are the quality requirements for medical non-woven fabrics?

1. Non-woven packaging materials should meet the requirements of "GB/T19663.1-2015 Packaging of Sterilized Medical Devices":

Microbial barrier properties, water resistance, compatibility with human tissues, air permeability, salt water resistance, surface absorption, toxicology experiments, equivalent pore size, drape, tensile strength, wet tensile strength and burst resistance, etc. All comply with relevant regulations and should be used once.

2. Storage environment requirements

The storage requirements of medical non-woven fabrics meet the requirements of YY/T0698.2-2009.

That is, the temperature of the inspection, packaging and sterilization area is 20℃-23℃, the relative humidity is 30%-60%, and mechanical ventilation is performed 10 times in 1 hour. The cotton dressing packing room must be separated from the equipment packing room to avoid cotton dust pollution of the equipment and packaging materials such as woven cloth.

3. Size requirements

①The equipment package of the operating room:

Please refer to the size of the instrument cart in the operating room. If you need to pack the instrument cart with non-woven fabric, the size of the non-woven fabric must be larger than 30cm around the sagging instrument cart.

② Irregularly shaped devices:

such as chest openers, electric drills, etc., choose net baskets to regularize them, and then use non-woven fabrics for packaging.

The round container such as cotton ball cylinder is placed in the middle of the non-woven fabric, the left and right sides of the wrapping fabric are folded back, then roll forward, and the wrapping fabric is folded back 3cm-5cm inward and then sealed.

③Frame hook type equipment:

In the inner packaging, the non-woven fabric can be fixed with tape to prevent it from loosening.

4. Other requirements

①Requirements for sharp or hooked devices

It is necessary to bring a protective cover for sharp equipment to prevent such equipment from piercing the non-woven fabric, resulting in equipment contamination and unnecessary waste of consumables.

②Requirements for overlapping items

Surgical basins, treatment bowls, etc. should be packaged separately as much as possible. If they need to be stacked, absorbent paper should be placed between the items to reduce the wet package rate.

③Requirements for small screws and drills

It is not suitable to directly use non-woven fabrics for packaging. It should be packed in precision instrument boxes with mesh holes before packaging.