1. Mechanical barrier

There are several cases of mechanical barriers:

a. Droplets larger than 5um in the air can be blocked by the filter material.

b. When the diameter of the fine dust is less than 3um, the fine dust is mechanically intercepted by the fiber layer of the curved channel in the mask filter material.

c. When the particle size and airflow velocity are both large, the particles are captured due to inertia colliding with the fibers. When the particles have a low flow rate and the particles are low, the particles are captured due to the Brownian motion impinging on the fibers.

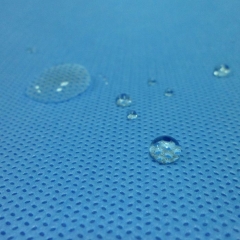

2. Electrostatic adsorption

In the production process ofmelt-blown cloth, electret treatment is usually carried out, so that the non-woven fabric can bring more static electricity and have electrostatic adsorption effect. Electrostatic adsorption refers to the capture of dust bacteria and viruses through the coulomb force of charged fibers when the fibers of the filter material are charged.

There are two ways to improve the charge storage capacity of electret materials:

a. By improving the crystallinity and mechanical deformation of the material, the structure of the material is changed, and an elongated hole channel is formed to prevent charge drift.

b. Generate charge traps by introducing additives with charge storage properties to capture charge.

3. Electret treatment

The key to improving the filtration efficiency of masks is the electrostatic storage ofmelt-blown non woven fabrics. At the current mask flow rate, the attenuation of static electricity is not enough (such as half a month to the user after leaving the factory), and normal medical masks are valid 6 months, and some masks in Japan are valid for three years.

Melt blown non woven electrets are very sensitive to environmental humidity. Saino's customers have done an experiment, stored at room temperature and high humidity (relative humidity greater than 95%) for 7 days, the surface potential of the positive and negative corona charging samples have decayed to 28% and 36% of the initial value, respectively. At this time, because the melt-blown non woven fabric has an open structure, its specific surface area is large, and it has a larger contact surface with the surrounding environment, making it more sensitive to moisture, corrosive gases, and heterogeneous charged particles in the environment. The corona charging system can only generate low beam energy ionic charges, and most of the injected charges are deposited on the near surface layer of the surface fiber of the cloth. When the sample is stored or operated in a high-humidity environment, a large amount of charge is lost due to the compensation effect of the polar groups in the water molecules and the heterogeneous ions in the atmosphere on the high concentration surface charge on the fiber. Therefore, in the process of transportation and storage of meltblown cloth, high humidity environment must be avoided.