Fiber web formation: The more popular technology for medical nonwovens is spunbond, meltblown and their composite materials (SMS) for specific end uses. When a stronger fiber web is needed, spunbond can be used. The spunbond web is strong in both the machine direction (MD) and the cross direction (CD). They are soft, porous and dimensionally stable. Spunbond is commonly used in products such as face masks, headwear, shoe covers, bed sheets and disposable clothes.

Bonding can be done by a variety of methods, including thermal bonding of synthetic fibers and their mixtures. Spunlace is the fastest growing bonding technology and has been clearly used in medical non-woven fabrics. It has a feel and touch similar to textiles and is suitable for products such as tulle, dressings, and hospital clothing.

Natural fiber processing: For cotton and rayon, it can be formed by air-laid/wet-laid or carded. Natural fibers are usually hydroentangled to give them most of the fabric-like properties. Although the final product obtained has excellent properties, it is expensive compared to synthetic fibers. Cotton is usually mercerized and bleached to increase its purity and thus get better acceptance in the medical and sanitary fields. Cotton also causes difficulties in processing due to its high dust content. Natural fibers find better applications in surgical gowns, cotton swabs and drapes, gauze, disposable clothing, bandages, wound dressings and other products. Cotton processing may include bonding techniques, such as resin bonding (for substrates), thermal bonding of polyolefin + cotton blends, and hydroentanglement for high-absorbency products.

Synthetic fiber process: Synthetic fiber is most often mixed with cotton/rayon. They are spunbonded and then bonded by any suitable bonding technique. Synthetic fibers can also be melt blown. For applications such as filters, face masks, etc., meltblown fiber webs are preferred because of their small fiber diameter and filtration efficiency.

Although synthetic fibers can be effectively bonded by any technology, this depends mainly on their end use.

Post-processing

The post-processing of medical non-woven fabrics should provide products with suitable finishes suitable for their specific end use. The different types of finishing agents used in medical non-woven fabrics are:

Detergent: bedding, nightgown and clothing used for multiple purposes. It can also be used for curtains, blankets, etc.

Softener: Make the fiber web feel soft to the skin. Can be used for disposable underwear, pillows, bed sheets, etc.

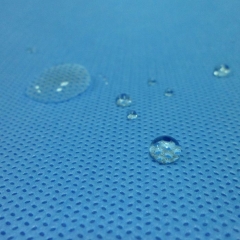

Water repellent: used for children's bed sheets, isolation clothing, etc.

Flame-retardant finishes: used for bedding, curtains, clothing, experimental coats, etc.

Antibacterial coating: very commonly used in gauze, dressings and sutures. The more popular one is silver nanocrystals.

Resin and manual additives: used in clothing, dresses, bed sheets, etc.