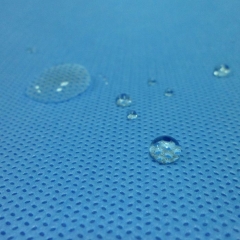

SS non-woven fabric: It is made by hot rolling of two layers of fiber mesh. The finished product is non-toxic and tasteless, and has high-efficiency isolation. Through special treatment of equipment and technology, it can achieve antistatic, anti-alcohol, anti-plasma, and water-repellent properties. .

SS: Spunbond non-woven fabric + spunbond non-woven fabric = two-layer fiber web hot rolled

Spunbond non-woven fabric, the main materials are polyester and polypropylene, high-strength, good high-temperature resistance. Spunbond non-woven fabric:

After polymer is extruded and stretched to form continuous filaments, the filaments are laid into a web, and the web is then After self-bonding, thermal bonding, chemical bonding or mechanical reinforcement, the fiber web becomes a non-woven fabric.

S is a single-layer spunbond non-woven fabric, and SS is a double-layer composite spunbond non-woven fabric.

S non-woven fabric / SS non-woven fabric difference:

Under normal circumstances, S and SS can be distinguished by softness.

S non-woven fabrics are mostly used in the packaging field, and SS non-woven fabrics are mostly used in sanitary materials. Therefore, in the mechanical design, the S machine tends to make the non-woven fabric stiffer, and the SS machine tends to make the non-woven fabric softer.

However, after a special process, S non-woven fabric has a softer feel than untreated SS fabric, which is suitable for sanitary materials; and SS can also be treated to become more rigid and suitable for packaging materials.

Another distinguishing latitude is the uniformity of the cloth, which refers to the stability of the weight per square meter, but it is difficult to distinguish by the naked eye.

In essence, the difference between S and SS non-woven fabrics lies in the number of nozzles in the machine. The number of letters in the name represents the number of nozzles, so S has one nozzle and SS has two nozzles.

Advantages and characteristics of SS non-woven fabric: S non-woven fabric is softer than other non-woven products.

The material it uses is polypropylene, which accounts for a relatively low proportion of the total. The fluffy feel is better than cotton, and the touch is skin-friendly. SS non-woven fabric is skin-friendly because it is soft and consists of many fine fibers.

All products made of fine fibers have strong air permeability, which can keep the fabric dry and easier to clean. This is a non-irritating, non-toxic product that meets the requirements of food-grade raw materials, and the fabric without any chemical substances is harmless to the body.

If you have other information about S/SS/SSS non-woven fabrics, please contact us.Email: long@guideco.cn