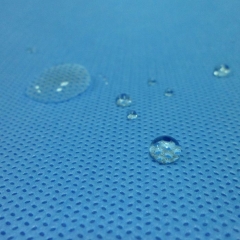

Meltblown non-woven fabrics use polypropylene as the main raw material, and use high-speed hot air flow to draw the thin stream of polymer melt extruded from the spinneret hole of the die, thereby forming ultra-fine fibers and collecting them on the condensation screen or roller. , and at the same time, it is bonded by itself to become a meltblown nonwoven fabric. Meltblown non-woven fabrics are white, flat and soft in appearance.

The fiber fineness of the material is 0.5-1.0um, and the random distribution of fibers provides more thermal bonding opportunities between fibers, so that the meltblown gas filter material has a larger specific surface area and a higher porosity (≥75%) . After high-voltage electret filtering power, the product has the characteristics of low resistance, high efficiency, and high dust holding capacity.

Meltblown non-woven fabric is an important material used in masks, air filters, wiping products, and composite fabrics. It is a non-fabricated non-woven fabric, and its filtration power is one of the factors that affect the price of the product. Meltblown grade and filter power are mutual. Filtration efficiency refers to the filtration power of meltblown. Because meltblown has the characteristics of filtering dust, particulate matter, dust, pollen and so on. The filtration grades of meltblown non-woven fabrics have the terms N, BFE, VFE, KN, FFP, and good meltblown grades will bring good filtration power. Poor meltblown grades result in poor filtration power. A good meltblown will be more expensive.

If you are interested in this product, please contact me!