Non-woven material is a new type of flexible material formed by processing high molecular polymers and fibrous aggregates through physical or chemical methods. It combines the advantages of the four flexible materials of textile, paper, plastic and leather. Spunlace non-woven materials are one of the non-woven materials with high technical content and good product style, and are highly praised by consumers. It has a development history of nearly 20 years in my country, ranging from ordinary non-woven materials to various functional non-woven materials. The materials have been developed and applied to a certain extent. The spunlace composite technology is a major innovation to the traditional spunlace technology. The spunlace composite technology enriches the performance and functions of spunlace products through the crossover, penetration and fusion of multiple technologies, and greatly expands the application fields of spunlace products.

Wood pulp composite spunlace nonwoven material is a kind of nonwoven composite material that uses spunlace technology to compound wood pulp fibers and synthetic fiber nets to form a structure of entangled two fibers. This kind of material has good wear properties such as high strength and stretchability, good hand feel, breathability and moisture permeability, and is widely used in the medical field based on the advantages of spunlace non-woven fabrics.

Although the softness and air permeability of spunlace non-woven fabrics are very good, the two indexes of synthetic blood penetration and filtration efficiency are not up to the standard if they are used to make protective clothing. Therefore, in addition to adding fine denier fibers to the raw materials, other processing techniques must be combined to completely solve the two problems of synthetic blood penetration and filtration efficiency.

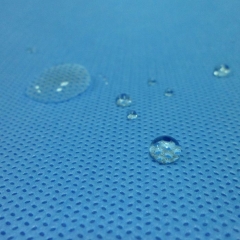

Water-repellent and flame-retardant multifunctional finishing of spunlace non-woven fabrics, giving the spunlace non-woven fabrics waterproof and flame-retardant effects;

The spunlace non-woven fabrics coated with composite processing to improve the filtration efficiency of the spunlace non-woven fabric.

After "three-proof (waterproof, alcohol-proof, blood-proof)" finishing, it becomes a medical surgical gown material and has been widely used abroad. The process method of using wood pulp paper and polyester fiber net for spunlace composite reinforcement is simpler than the method of using wood pulp fiber air-laid and polyester fiber net spunlace composite method, and the equipment is simpler and the cost is lower. Most domestic enterprises use this method to produce wood pulp composite spunlace material.

In addition, the commonly used surgical drapes, surgical gowns, etc. are also made of non-woven fabrics and polyethylene (PE) membranes. The products do not shed hair, do not fade, and have good air permeability. The technology and protective clothing are basic The same, but the relevant standards will be different.