But how are nonwovens suitable for electronic products, and what are the important things to consider when producing products for this market? Let's look at some options.

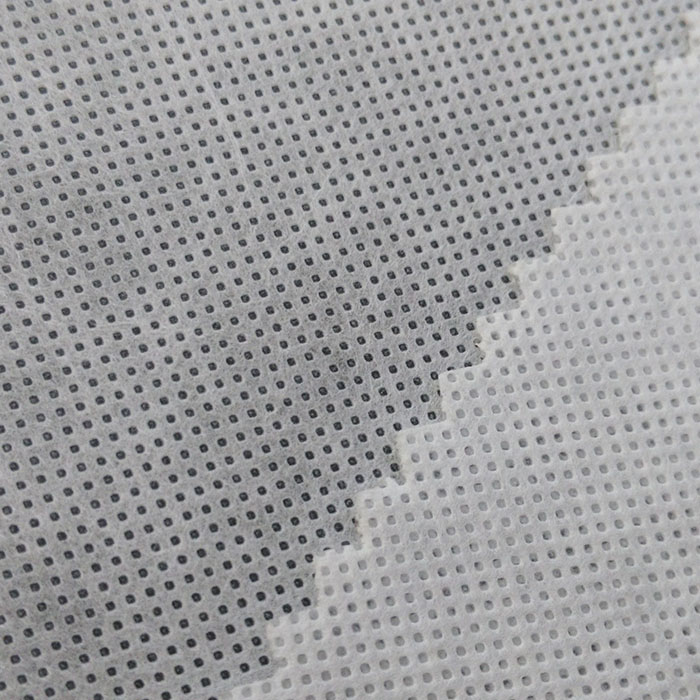

Battery separator. Ordinary consumers may not even consider the components in the battery box at all. Things are fine, right? Well, what we are saying is that if consumers don’t have to think about this, then we’re doing our job. This is an innovative corner of the market. All commercial batteries use separators. They must have insulating properties to prevent short circuits, resist oxidation, pores large enough to allow ions to flow, low electrical resistance and wettability. According to a report in "Nonwovens Industry" magazine, Dreamweaver International and its manufacturing partners began to produce 20-micron thin lithium ion battery separators. One of Dreamweaver's separators can withstand temperatures up to 300°C. This is an important consideration for applications such as large-scale energy storage and extended-range electric vehicles.

Cable winding. Insulation properties, tensile strength and flexibility make nonwoven fabrics the choice of cable winding for power cables, industrial cables and communication cables. According to the application, nonwoven fabric manufacturers can produce fabrics with high porosity, aging resistance, temperature change resistance, compressibility and high resistivity.

Electrical insulator. From the consumer's point of view, these are very important. Insulators can be used in all electrical equipment, and when the insulator fails, the electrical products will not work. The insulating material must have low conductivity and not easily penetrate. Depending on the application, the manufacturer must work with a non-woven fabric partner to ensure that the insulating non-woven fabric has all the required properties to prevent equipment failure.

We have said before that nonwoven fabrics are everywhere. These are just a few examples of nonwoven materials in electronics. There is always room for growth in the entire market, and all indicators show that this area of the nonwoven market is also expanding.